Features

40A solid state relay (SSR) with 70-280V AC input features high structural strength, good impact resistance, and strong shock resistance. The SSR offers a reliable switching the commercial and industrial loads, such as computer peripheral interface device, printing machine, molding machine, food machine, packaging machine, and so on.

- Built in RC absorption

- Photoelectric isolation

- SCR output

- LED indicator for operation status

- Removable protective cover for safety

- Panel mount

- Zero-crossing switch type

Specification

| Model | ATO-SSR-DH40AA | |

| Input | Control voltage range | 70-280V AC |

| Max. input current | 15mA | |

| Must operate voltage | 70V AC | |

| Must release voltage | 50V AC | |

| Output | Load voltage range | 24-480V AC |

| Peak voltage | 800V AC | |

| Maximum load current | 40A | |

| Maximum off-state leakage current | 2mA | |

| Maximum off-state time | 10mS | |

| Maximum on-state voltage drop | 1.5V | |

| General | Type | AC to AC, single phase |

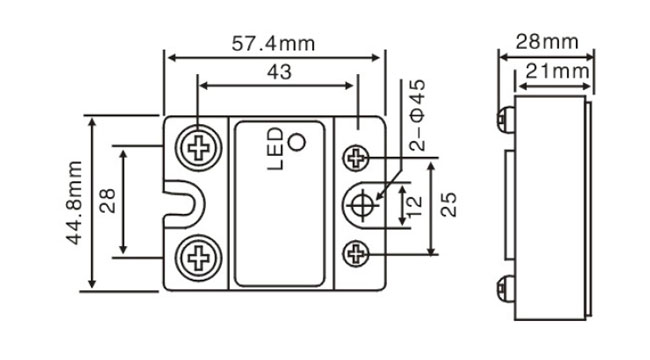

| Dimension L – W – H (mm) | 57.4х44.8х28 | |

| Weight | 135g | |

| Dielectric strength (input to output) | 4000V | |

| Dielectric strength (input, output to the base) | 2500V | |

| Operating temperature | -20℃~ 80℃ | |

| Mount | Panel | |

| Certification | CE | |

Note:

- When the load is a resistive load, the maximum load current of the selected SSR should be 2~3 times greater than the actual load current;

- When the load is an inductive load, the maximum load current of the selected SSR should be more than 7~8 times the actual load current.

- When the maximum load current is higher than 10A, a heat sink must be installed to the solid state relay, or the SSR relay should be mounted on a metal base plate with heat dissipation effect, and the thermal grease is applied between them.

Dimension (Unit: mm)

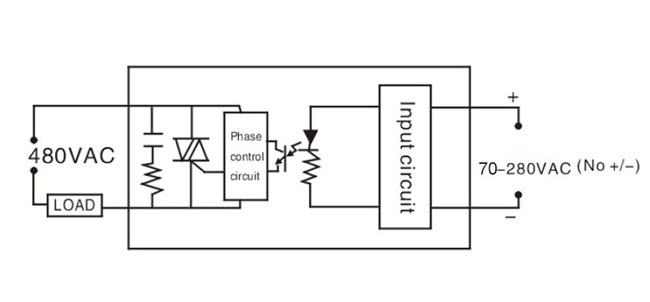

Wiring Diagram

Tips: Installation methods of solid state relays

Horizontal W-type and vertical L-type of solid state relays in small sizes are suitable for direct welding installation on the printed circuit board (PCB). Vertical L2-type is not only suitable for welding installation on circuit board, but also can be applied to socket installation on the circuit board. In the selection of SSRs used in PCB under small current standard, welding temperature should be less than 250 ℃, and time is limited to 10s since the lead terminal is made of high thermal conductivity materials. Given the ambient temperature, derating use can be considered if necessary. The load current is generally controlled within 1/2 of the rated value.

K-type and F-type are suitable for installation on radiators and instrument baseplates. In case of high-power SSRs (K-type and F-type package) installation, it should be noted that contact surface with the radiator is smooth, and is coated with thermal grease. The larger the installation torque, the smaller the contact resistance. It is necessary to equip high-current leads with cold welding flakes to reduce contact resistance of the lead wire.

Reviews

There are no reviews yet.